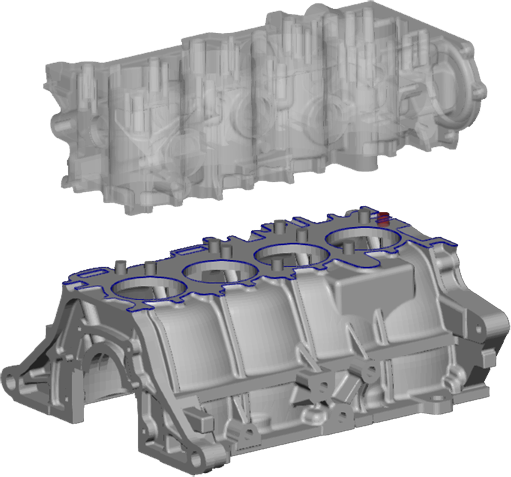

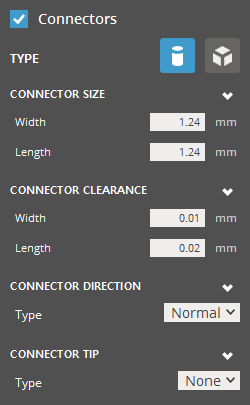

Connectors

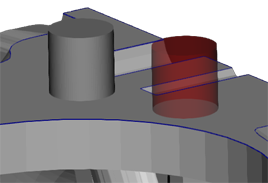

Type - Select Cylinder or Cube connectors.

Connector Width (Min. 0mm) - width of the connector.

Connector Length (Min. 0mm) - length of the connectors.

Connector Clearance

Clearance Width (Min. 0mm) - width of the clearance between the connector and the part.

Clearance Length (Min. 0mm) - length of the clearance between the connector and the part.

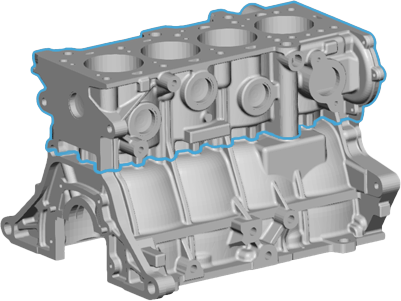

Connector Direction

Type - Direction of the connector. Normal direction is perpendicular to a cutting plane. Primary Axis or Plane is selectable as the direction of the connector.

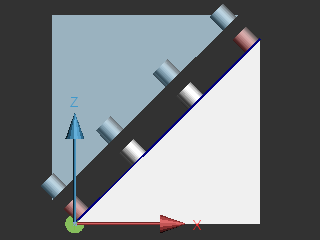

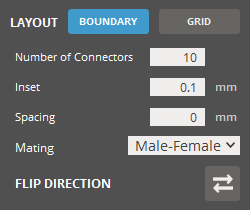

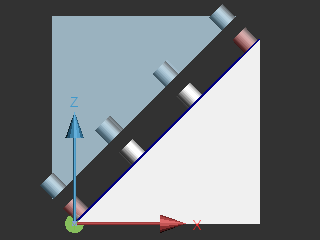

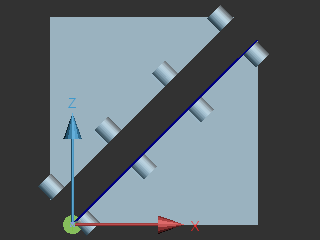

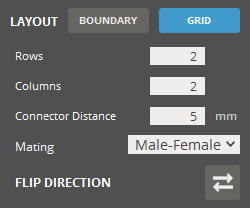

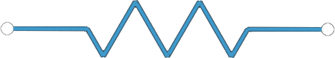

|

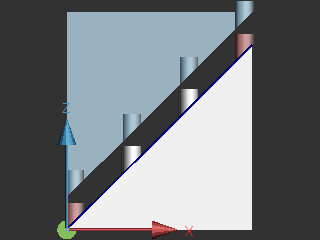

|

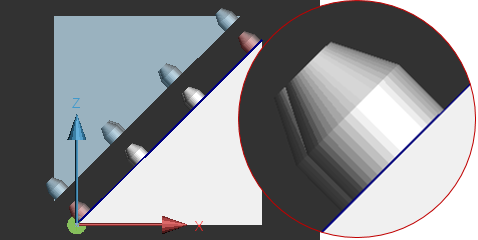

Normal |

Primary Axis |

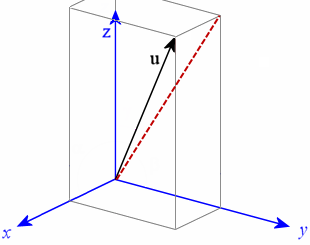

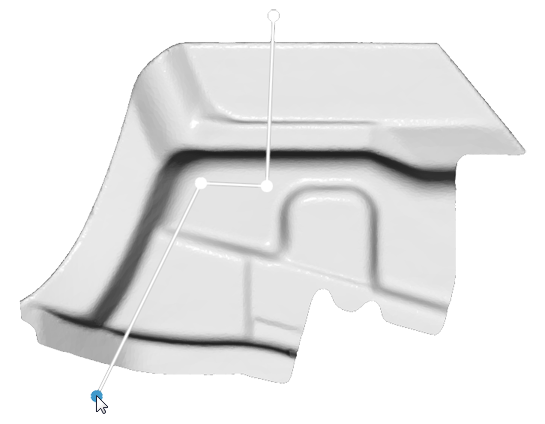

Note: The largest component of the normal of the cutting plane is the primary axis. The largest 2 components of the normal of the cutting plane is the primary plane. (For example, if the normal of the cutting plane is "u" in the image below, the primary axis is Z axis, the primary plane is the YZ plane; the U vector is projected to the YZ plane. (See the red-dotted line)

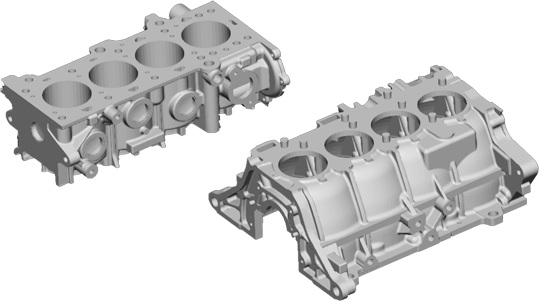

Connector Tip

Type - Tip type of the connector. Sphere or Chamber is selectable as the type of the connector. Specify the with or length of the connector.

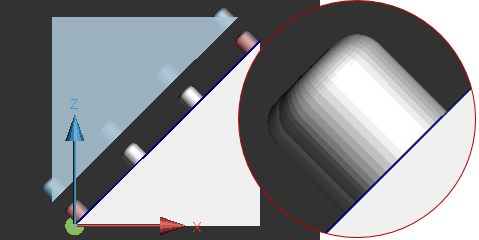

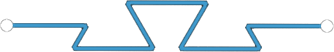

|

|

Sphere |

Chamfer |

Male Only - select to define the tip of the connect on the Male part only.

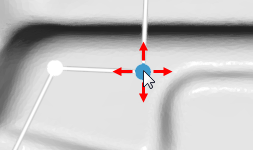

, or

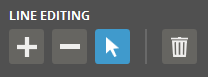

press the

, or

press the